Research Groups

| Group Name | Leader |

| Cyanobacterial Synthetic Biotechnology Group | LUAN Guodong |

| Filamentous fungi Synthetic Biotechnology Group | HUANG Xuenian |

| Yeast Synthetic Biotechnology Group | - |

| Microbial Synthesis Supporting Technologies Group | XU Huifang |

| Microbial Process Engineering Group | ZHANG Kai |

| Microbial Fermentation Engineering Group | - |

| Admin Team | GUO Qing |

Research Interest

Cyanobacteria based photosynthetic production of biofuels and biochemicals; Cyanobacterial physiological and metabolism mechanisms to adapt to diverse environmental stresses; Genome mining and biosynthetic mechanisms of fungal natural products; Development of filamentous fungi cell factories for green biomanufacturing; Molecular enzyme engineering and novel biocatalytic transformation; Functional and mechanistic elucidation of key protein elements in microbial physiological and metabolic processes."

Research Fields

Cyanobacterial Synthetic Biology, Cyanobacterial Genetics, Physiology and Metabolism, Photosynthetic Biomanufacturing, Filamentous fungi Synthetic Biology, Microbial Fermentation Engineering, Computational Biology, Molecular Enzyme Engineering and Novel Catalytic System, Protein engineering and Structural Biology, Natural Products Biosynthesis

Representative Research

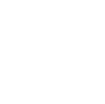

1. Development of cyanobacterial photosynthetic cell factories

Through deciphering and engineering of cyanobacterial photosynthetic metabolism network, the researchers have facilitated efficient photosynthetic conversion of carbon dioxide into biofuels and biochemicals, including ethanol, ethylene, sucrose, trehalose, glycerol glucoside, fatty alkanes, and fatty alcohols. These works have been published in Energy & Environmental Science, Metabolic Engineering, Biotechnology for Biofuels, et al.

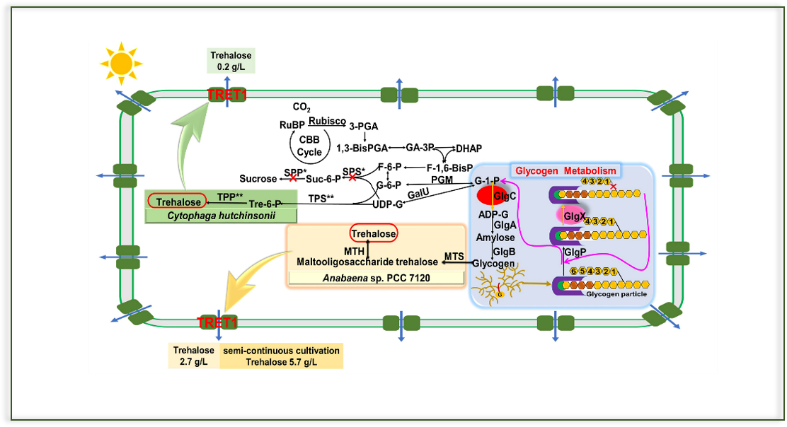

2. Deciphering of the genetic and physiological mechanisms of cyanobacteria to resist environmental stresses

Combining system biotechnology, synthetic biology, and germplasm resource mining, the researchers disclosed mechanism of cyanobacteria cells to adapt to diverse environmental stresses, including strong illumination, high temperature, and concentrated salts, and the obtained functional genes, modules, and strategies, have been utilized to improve cellular robustness of cyanobacteria cell factories. These works have been published in Applied & Environmental Microbiology, Frontiers in Microbiology, Biotechnology for Biofuels, et al.

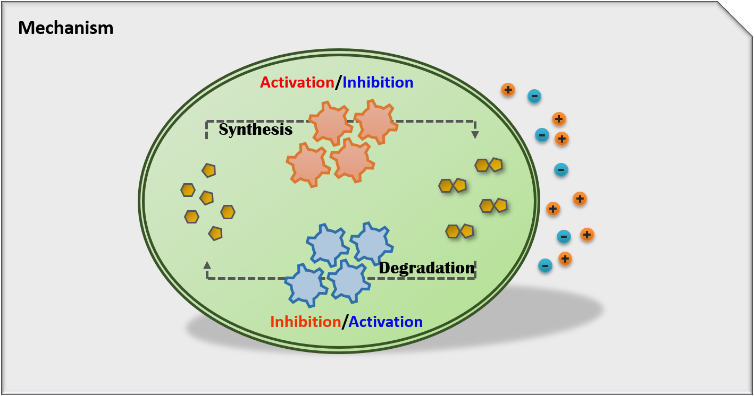

3. Genome mining of fungal natural products

The researchers have revealed an interesting biosynthetic mechanism of natural products in filamentous fungi. A new mode of coordinated crosstalk between two separate gene clusters containing four core-biosynthetic genes to generate the new azaphilone compounds was observed in Aspergillus terreus. This is a meaningful mechanism of fungal secondary metabolism, which allows fungi to synthesize more complex compounds and gain new physiological functions. The results provide a new insight into fungal natural product biosynthesis.

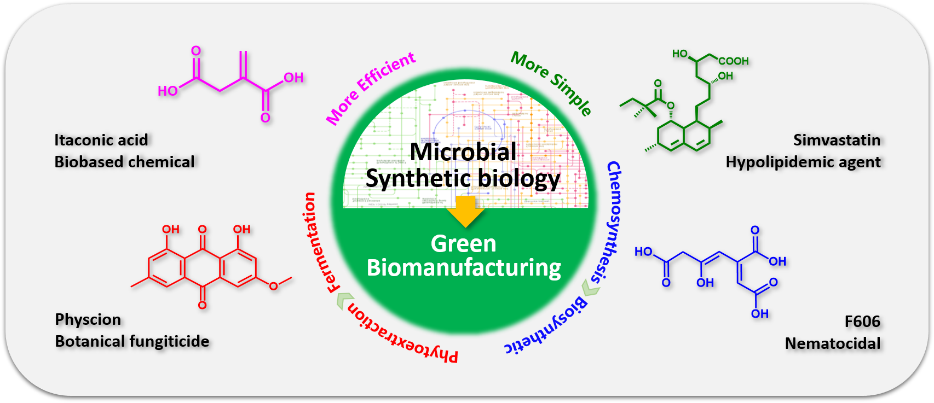

4. Filamentous fungi cell factories for green biomanufacturing

The researchers focus on the technological upgrading of production processes of important chemicals, including pharmaceuticals, pesticides and bio-based chemicals. Through synthetic biology strategies, we have developed more efficient, economical and greener production technique in cooperation with Big Pharma.

(1) Established the first microbial fermentation production line of the novel nematocide F606;

(2) Created a microbial cell factory that can efficiently synthesize plant-derived fungicide physcion;

(3) Developed a simpler biosynthetic production process for the lipid-lowering drug simvastatin.

5. Advanced biomanufacturing of Glycerylglucoside (GG) from Spirulina

The biomanufacturing technology of the high-value Glycerylglucoside (GG) from Spirulina was developed by setting up a novel SCGP (Smart Cyano Glycerylglucoside Polygeneration) technology. Compared with the traditional production processes such as enzymatic catalysis and chemical synthesis, the SCGP technology realized green production of natural 2-α-GG based on the innovations on special cultivation, efficient harvesting, and nondestructive extraction process of the natural Spirulina cells and the establishment of the entire process chain, and the products have been put into market. The finally obtained high-purity GG products (>99%) met the application requirements for quality, efficacy and safety from the cosmetics, food, and pharmaceutical industries, and the Spirulina biomass with well-maintained yield and property was simultaneously harvested as by-product still reaching national standards. The SCGP technology could be expected to bring in significant improvement for the economic potentials of current Spirulina industry.

Contact

lvxf@qibebt.ac.cn