Recycled Micro-sized Silicon Anodes from Photovoltaic Waste Improve Lithium-ion Battery Performance

Researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences have developed low-cost micro-sized silicon anodes from recycled photovoltaic waste using a novel electrolyte design.

Their pioneering work, published in Nature Sustainability on July 16, offers a path to more sustainable, low-cost, and high-energy-density batteries that could transform energy storage systems for electric vehicles and renewable energy applications.

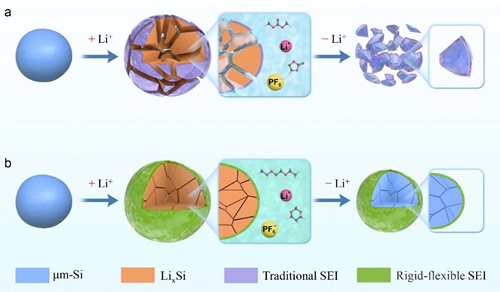

Silicon anodes are favored for their ability to substantially increase the energy density of lithium-ion batteries compared to traditional graphite anodes but are hindered by significant volume expansion during charge-discharge cycles. This expansion can cause mechanical fractures and degrade battery performance.

To overcome these challenges, the researchers, led by Prof. CUI Guanglei, pioneered the use of micro-sized silicon (μm-Si) particles derived from photovoltaic waste as a viable alternative.

When integrated with a specially designed ether-based electrolyte, these μm-Si anodes exhibit remarkable electrochemical stability, maintaining an average coulombic efficiency of 99.94% and retaining 83.13% of their initial capacity after 200 cycles.

"This work not only suggests a more sustainable supply source for silicon particles but also addresses the major challenges facing micro-sized silicon anode materials," said Dr. LIU Tao, first author of the study.

The secret to the anodes' success lies in their unique solid-electrolyte interphase (SEI) chemistry, a result of the team’s innovative electrolyte composition of 3 M LiPF6 dissolved in a 1:3 volume ratio of 1,3-dioxane and 1,2-diethoxyethane. This formulation fosters the development of a dual-layer SEI that is flexible yet robust, holding together fractured silicon particles while improving ionic conduction and minimizing side reactions.

The NCM811||μm-Si pouch cells with the new anode and electrolyte combination survived 80 cycles and delivered an impressive energy density of 340.7 Wh kg-1 under harsh conditions. This performance is a significant improvement over conventional lithium-ion batteries, which are approaching their energy density limits.

Dr. DONG Tiantian, another co-first author of the study, emphasized the environmental benefits: "the sustainable sourcing of silicon from discarded solar panels mitigates both the economic and environmental impacts of photovoltaic waste. Converting waste into valuable battery components significantly reduces the cost of lithium-ion batteries and increases their accessibility."

"By using recycled materials and advanced chemical engineering, we have demonstrated that high-performance and environmentally sustainable lithium-ion batteries are not only possible, but also within reach," said Prof. CUI, who is optimistic that this research will lead to the development of next-generation batteries capable of powering everything from electric vehicles to grid-scale energy storage.

This groundbreaking approach exemplifies how innovative recycling and meticulous materials science can converge to solve some of the most pressing challenges in energy technology today.

Comparative influence of solid-electrolyte interphase (SEI) on microsized silicon anodes during cycling between traditional electrolyte (a, Mixed inorganic-organic SEI) and the electrolyte developed in this study (b, Rigid-flexible coupling SEI).

(Text/Image by LIU Tao)

Contact:

KONG Fengru

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-58261072

E-mail: kongfr@qibebt.ac.cn