New Sulfur-Free Catalyst Realizes Efficient Green Diesel Production

Green diesel, a blend of diesel-grade hydrocarbons derived from renewable oils such as vegetable oils and animal fats, offers a promising alternative to traditional petroleum diesel. With a chemical composition similar to petroleum diesel, it integrates seamlessly into existing engines, making it an environmentally friendly fuel choice that can significantly reduce CO2 emissions by over 50%.

The predominant method for industrial green diesel production involves hydrotreating technology using sulfided CoMo or NiMo catalysts. However, the maintenance of these catalysts requires continuous replenishment of the sulfur source during operation, leading to increased costs, equipment corrosion, and sulfur contamination. Hence, the quest for a non-sulfur catalytic system to enhance efficient green diesel production is paramount.

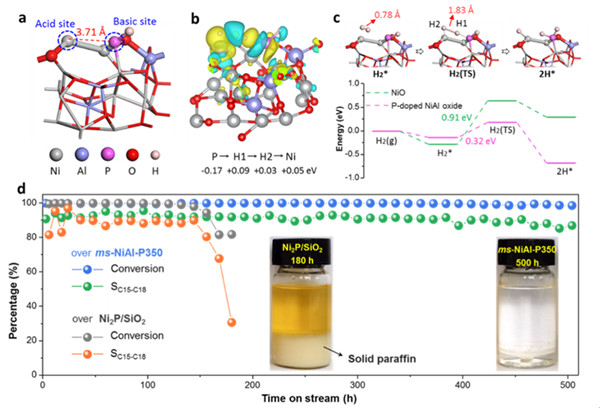

In a breakthrough development, researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology of the Chinese Academy of Sciences have developed a robust P-doped NiAl-oxide catalyst with frustrated Lewis pairs (FLPs). This innovative catalyst enables the efficient conversion of various feedstocks into green diesel without the need for sulfur replenishment.

The study, published in Nature Communications on April 12, reveals the extraordinary capabilities of the P-doped NiAl oxide catalyst. It can continuously convert soybean oil to diesel-range hydrocarbons for 500 hours without deactivation, outperforming commercial systems with a higher weight hourly space velocity (WHSV) of 6.0 h-1 compared to the typical range of 0.5~3.0 h-1.

In addition, this catalytic system shows versatility in processing different feedstocks such as palm oil, duck fat, and waste cooking oil.

Dr. LI Dechang, lead author of the study, said that the industrial viability of their hydrotreating system was demonstrated by scaling up the catalyst to convert renewable oils into green diesel consistently over 1,000 hours of operation.

This study underscores the superior catalytic activity, stability, cost-effectiveness, and environmental attributes of the FLPs catalyst. With the potential to outperform conventional sulfided metal catalysts, this catalytic system heralds a more efficient and sustainable approach to green diesel production. It marks a pioneering achievement in green diesel production, as acknowledged by Dr. LI, solidifying its novelty and impact in the field.

Fig. 1 Hydrotreating of soybean oil to produce green diesel over the FLPs catalyst in this work. Reaction conditions: T=350 °C, PH2=3.0 MPa, WHSV=6.0 h-1.

(Image by LI Dechang)

(Image/Text by LI Dechang)

Contact:

KONG Fengru

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-58261072

E-mail: kongfr@qibebt.ac.cn