Magnesiophilic Three-Dimensional Substrate Enables Planar Electroplating/Stripping Process of Magnesium Metal Anode

As a promising candidate to current lithium-ion batteries, rechargeable magnesium batteries have attracted extensive attention due to the superior properties of magnesium (Mg) metal anodes, such as high volumetric capacity (3833 mAh/cm3), abundant resources, environmental friendliness, and uneasy to grow dendrites.

Although some literatures have reported that the morphology of Mg dendrites can be observed under extreme electroplating conditions, such as using the limited Mg electrolytes with low Mg-ion conductivity and applying ultra-high current density (10 mAh/cm2), these test conditions are clearly different from practical requirements.

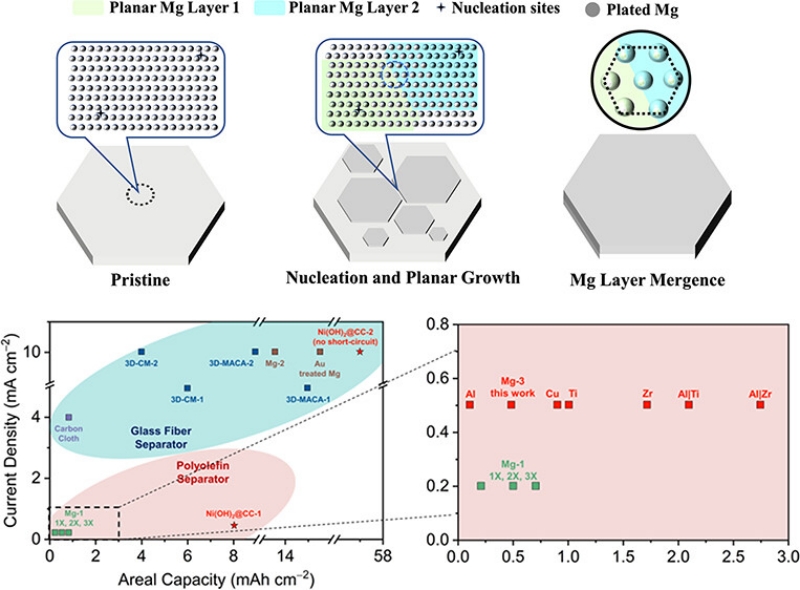

Researchers from the Qingdao Institute of Bioenergy and Bioprocess Technology of the Chinese Academy of Sciences (CAS) have discovered that the use of the practical polyolefin separator indeed causes the short-circuit of coin cell even at the low current density. They have established a layer-by-layer planar growth model for short-circuit suppression, and proposed the design strategy of 3D magnesiophilic to achieve planar Mg electroplating/stripping behavior.

The study was published in ACS Energy Letters on Dec. 4.

Ample evidence has shown that Mg growth is uniform and dense when the current density is below five mAh/cm2. However, using practical polyolefin separators with the thin thickness, low-current charging and discharging can cause internal short-circuiting in coin cells.

The researchers have proposed the island-growth model for Mg deposits based on electrochemical tests and microscopic morphology observation, which reasonably explains the abnormal short-circuit behavior.

By further adjusting the lattice mismatch parameters and the surface energy of the substrate, the layer-by-layer planar growth of Mg deposits is achieved, effectively solving the above abnormal short-circuit problem.

The researchers used a magnesiophilic three-dimensional substrate (Ni(OH)2@CC) with low lattice mismatch and high surface energy properties as an electroplating substrate, which not only enabled the reversible electroplating/stripping process, but also matched with a high-load Mo6S8 cathode (30 mg/cm2) .

By thoroughly exploring of the short-circuit phenomenon caused by abnormal non-dendritic electroplating behavior in RMBs and proposing validated solutions, this work provides an important driving force for the practical application of Mg metal anode.

Schematic diagram of layer-by-layer planar growth model of Mg deposits and the performance comparison of various electroplating substrates

(Image and Text by WANG Guixin & DU Aobing)

Contact:

KONG Fengru

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-58261072

E-mail: kongfr@qibebt.ac.cn