Novel Strategies to Accelerate the Application of High-Energy Lithium Metal Batteries

The development of LMBs with energy density exceeding 500 Wh kg-1 has garnered significant attention, especially in the special scenario applications. However, due to the strong reduction capability of Li metal anode, the parasitic side reactions between conventional carbonate electrolytes and Li metal are severe, leading to a range of issues such as Li dendrite growth and Li anode pulverization, ultimately resulting in significantly reduced safety and cycle life of LMBs. Furthermore, the uncontrollable cross-talk effect of byproducts from cathode interface reactions can exacerbate the failure of Li anode. Therefore, it is crucial to employ advanced characterization techniques to elucidate the microscopic mechanisms behind the performance degradation of LMBs and to develop advanced electrolytes.

Recently, a research team led by Prof. CUI Guanglei from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS), has made significant progress in the field of high specific energy lithium metal batteries (LMBs).

The study was published in Energy & Environmental Science on April.

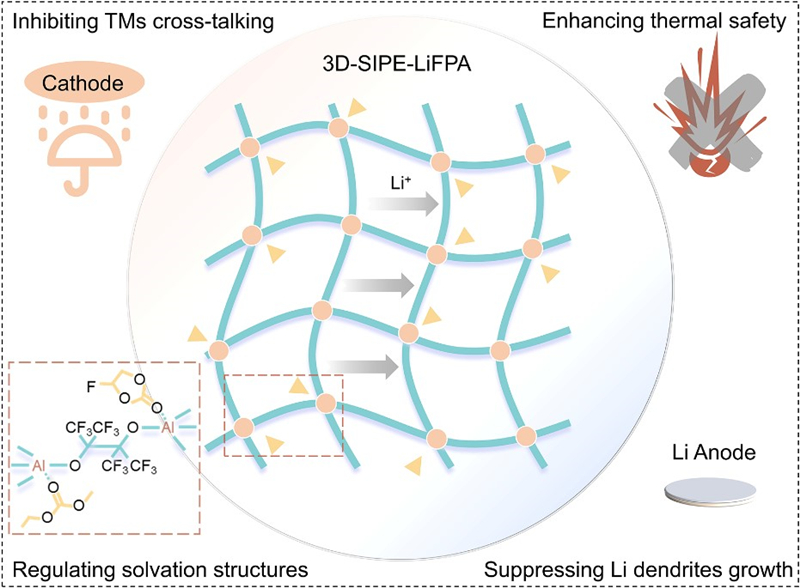

To address the aforementioned issues, this work has further developed our proposed in-situ solidification technology. This work has successfully synthesized a novel aluminum-centered Li salt and utilized it as a monomer for thermally induced in-situ solidification, thereby constructing a novel 3D single-ion conducting polymer electrolyte (3D-SIPE-LiFPA) for LMBs. Compared to conventional polymer electrolytes, 3D-SIPE-LiFPA exhibits unique structural features, which promote the formation of a protective solid electrolyte interface (SEI) layer enriched with LiF and Al-containing species on the Li anode. 3D-SIPE-LiFPA endows high energy density pouch-type LMBs (437 Wh kg-1) with long cycle life and high thermal safety. Our work successfully enhances both the cycle life and safety of high energy density pouch-type LMBs and sets a precedent of polymerizing lithium salt anions as polymer electrolyte for LMBs, which will be an important milestone of polymer electrolyte for boosting the development of both LMBs and LIBs.

The wide-temperature-range LMBs developed using this technology achieve an energy density exceeding 550 Wh kg-1, making them particularly suitable for deep-space unmanned aerial vehicles (UAVs) applications. This technology has also been demonstrated in Plant Protection UAVs for an extended period. This work reveals the crucial role of modifying solvation structure of carbonate electrolytes in improving its interface compatibility with Li anode.

"The aforementioned achievements have laid a solid foundation for the special scenario applications of high specific energy LMBs with long life and high safety" said Prof. CUI.

In-situ polymerized lithium salt as a polymer electrolyte for high-safety lithium metal batteries(Image by ZHANG Shenghang, Xu Gaojie, Cui Zili )

(Text by ZHANG Shenghang, Xu Gaojie, Cui Zili)

Contact:

KONG Fengru

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-58261072

E-mail: kongfr@qibebt.ac.cn