Hydrogen Purification through a Highly Stable Dual-phase Oxygen Permeable Membrane

Compared with hydrogen production through renewable energy electrolytic water technology, currently obtaining hydrogen fuel by purifying industrial by-product hydrogen is considered to be a more realistic and inexpensive way due to the low operating cost in hydrogen fuel cells. The presence of CO impurities in hydrogen fuel can rapidly poison the catalyst inside fuel cells, thus developing CO-free hydrogen (CO≦0.2ppm) preparation technology has become an important research direction in hydrogen energy. The dense ceramic membrane with mixed oxygen ion-electron conductivity has 100% selectivity for oxygen transport.

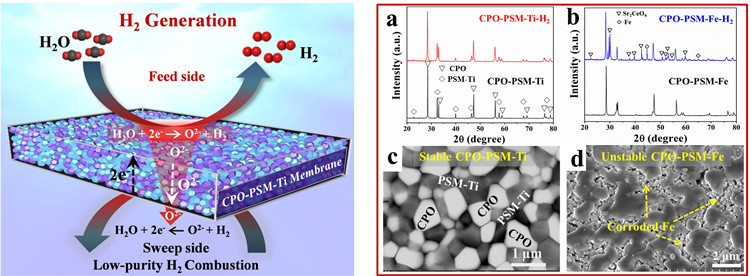

When the high-temperature water decomposition reaction and the industrial byproduct hydrogen combustion reaction are coupled on both sides of the ceramic oxygen-permeable membrane reactor, the combustion of low-purity hydrogen can expedite the in situ removal of oxygen generated by water decomposition. Therefore, it can efficiently promote water decomposition and directly obtain CO-free hydrogen that can be used in hydrogen fuel cells.

Recently, Prof. JIANG Heqing, a researcher from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy of Sciences (CAS), and Prof. Caro from Hanover University of Germany, jointly developed a novel titanium based dual-phase oxygen permeable membrane.

Compared with the chemically unstable iron-based membrane, the Ti-based membrane can retain its original phase structure and microstructure after being treated under the harsh atmosphere containing water vapor and hydrogen for 100 hours, exhibiting excellent anti-reduction stability. This dual-phase oxygen permeable membrane exhibits good oxygen permeability in reducing atmosphere and can be used as a membrane reactor for hydrogen purification. The CO-free hydrogen can be efficiently obtained from the water decomposition driven by the low-purity hydrogen combustion reaction.

The experimental results indicate that the Ti-based dual-phase membrane can steadily operate for a long time. A high hydrogen production rate of 0.25 m3 h-1 m-2 was enabled. This work solves the poor stability problem of traditional membrane in reducing atmosphere and promotes the development of hydrogen production technology based on ceramic membrane.

This work has been published in the authoritative journal Angew. Chem. Int. Ed. and was financially supported by National Natural Science Foundation of China, the Director Innovation Fund of Key Laboratory of Biofuels, CAS and QIBEBT, and Dalian National Laboratory For Clean Energy (DNL), CAS.

Fig.: Hydrogen production via Ti-based oxygen permeable membrane reactor. Comparison in stability of Ti-based and Fe-based dual-phase membranes. (Image by JIA Lujian)

(Text by JIA Lujian)

Contact:

CHENG Jing

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-80662647/80662622

E-mail: chengjing@qibebt.ac.cn