Scientists Develop Highly Efficient Synthetic Methodology of Ultra-high Molecular Weight Polyisoprene Rubber

In China, the polyolefin industry has a general phenomenon of big but not strong. Particularly in high end polyolefin materials, there is a gap with the foreign countries.

Branched ultra-high molecular weight polydiene rubbers emerge remarkable mechanical properties, such as high tensile strength, high wet-slip resistance andhigh damping performance, which has clear applications in high-performance tires and noise-reducing materials.

However, efficient and precise synthetic approach of the ultra-high molecular weight rubber is still a thorny subject, which limits its preparations and applications.

The Catalytic Polymerization and Process Group of Qingdao institute of bioenergy and bioprocess technology (QIBEBT), led by Professor WANG Qinggang, has been committed to the development of novel functional rubber materials.

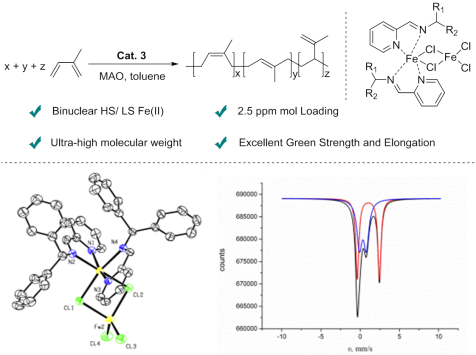

Recently, they proposed a highly efficient strategy of ultra-high molecular weight branched polyisoprene rubber synthesis, utilizing a novel asymmetric binuclear chlorinated bridge iron catalyst. The relevant research was published in Chemical Communications.

The chloride-bridged unsymmetrical complexes consisted of mixed Fe(II)-HS/Fe(II)-LS binuclear structures, and exhibited extremely high catalytic efficiency, as 1 g catalyst is enough to produce 30 Kg polyisoprene rubber (Mn = 1.8 × 106 g/mol). The resulting polyisoprene rubber has superior green strength and elongation at break, showing potential industrial application prospects (Figure 1).

Figure 1: Unsymmetrical binuclear iron complex for the efficient synthesis of polyisoprene. (Image by WANG Liang and YANG Weiying)

The first author of this paper is Dr. WANG Liang of QIBEBT. The research was generously supported by the Major Science and Technology Innovation Program of Shandong Province, ‘135’ Projects Fund of CAS-QIBEBT Director Innovation Foundation, the DICP& QIBEBT United Foundation and the National Natural Science Foundation of China.

(Text by WANG Liang and YANG Weiying)

Contact:

CHENG Jing

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-80662647/80662622

E-mail: chengjing@qibebt.ac.cn