A Novel Consolidated Bio-Saccharification Technique for Lignocellulose Conversion

The industrial conversion of biomass to high-value biofuels and biochemical is mainly restricted by lignocellulose solubilization. Currently, three strategies are reported for lignocellulose bioconversion: separate enzymatic hydrolysis and fermentation (SHF), simultaneous saccharification and fermentation (SSF) and consolidated bioprocessing (CBP).

For SHF and SSF, cellulases are usually produced by fungi aerobically in a different reactor and the enzyme cost is an essential issue to consider. CBP integrates the enzyme production, cellulose hydrolysis, and fermentation in one step to reduce cellulase and investment costs, but is with low saccharification efficiency and relatively simple products.

The Metabolomics Group from Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS) developed a novel strategy termed consolidated bio-saccharification (CBS) for cost-efficient lignocellulose conversion, which combines cellulase production and hydrolysis but separates fermentation from the integrated process and takes fermentable sugar as the target product to couple various downstream fermentation processes.

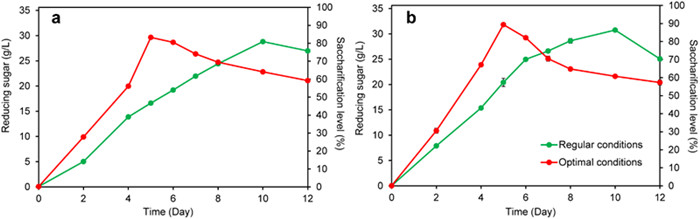

The researchers had previously developed a CBS biocatalyst by genetic engineering of Clostridium thermocellum, but it takes a long time to reach a high saccharification level. Then, a second generation of CBS biocatalyst was developed and key process factors, including the medium, inoculum, substrate load, etc, were optimized to promote the saccharification efficiency and further reduce the cost.

Under the optimal conditions, the CBS process was shortened by 50% with pretreated wheat straw as the substrate. Now, the sugar yield reached 0.795 g/g and the saccharification level was 89.3% (Figure 1). “CBS is expected to be widely used in producing various lignocellulose-derived chemicals, functional foods and pharmaceuticals. The construction of a pilot-scale CBS demonstration is undergoing.” says Prof. Cui, the corresponding author of the study.

Contact:

CHENG Jing

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Tel: 86-532-80662647

E-mail: chengjing@qibebt.ac.cn