Novel Slurry Reactor for Process Intensification

Slurry reactor is a gas-liquid-solid reactor where particles act as the catalyst. It is very popular in many industries such as the energy and chemical industry, fine chemistry industry, sewage treatment. Separation and collection of catalyst particles from the slurry containing the final products are time and energy consuming. Process intensification technology of reaction and separation for slurry reactor is highly desired to reduce the cost.

Recently, a novel slurry reactor for the process intensification of gas-liquid reaction and solid-liquid separation was invented by the research team led by Prof. YANG Chao from Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences (CAS). In this novel slurry reactor wherein the processes of mixing, reaction and separation were coupled, an internal airlift loop reactor (IALR) and a hydrocyclone with low-energy costs for solid-liquid separation were successfully integrated.

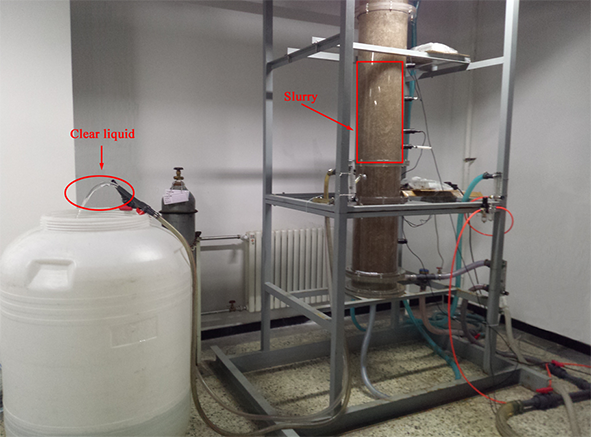

In a tested pilot reactor, the slurry can be mixed well in the reactor due to the prominent advantage of directional flow in IALRs. The reaction in the liquid phase and mass transfer between the gas and the liquid phases are taken as well. Particle catalysts are first separated by the hydrocyclone in downcomer and then recirculated and uniformly suspended again from the underflow of hydrocyclone to the riser of IALR. The clear products in the liquid phase are simply obtained from the overflow of hydrocyclone. A glance of this new reactor during the experiments is shown in the following image.

Figure 1. The qualitative test for the gas-liquid-solid system. (Image by YANG Tao)

“This new type of slurry reactor can be operated continuously and avoid the post-treatment of the slurry, and it can cut down the operation cost considerably”, says the corresponding author HUANG Qingshan of this study.

The related findings were published in Chemical Engineering Science. Additionally, national (201610941001.5) and PCT (PCT/CN2017/102163) patents had been applied. The research was supported by the National Key Research and Development Program of China (2016YFB0301701), the National Natural Science Foundation of China (91434114, 21376254), and the Instrument Developing Project of the Chinese Academy of Sciences (YZ201641).

(Text by YANG Tao)

Tel: 86-532-80662647

E-mail: chengjing@qibebt.ac.cn