Sustainable Jet/Diesel Fuels Produced from Biomass

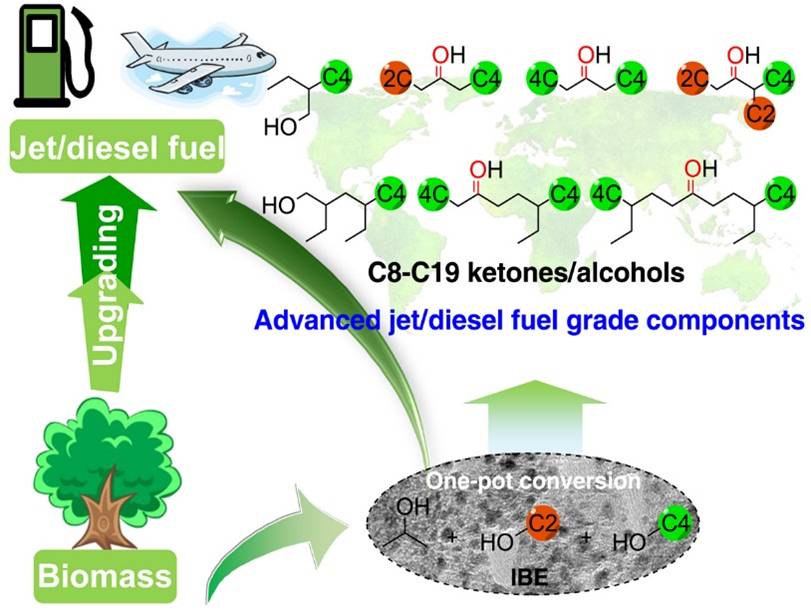

You may know the gasoline (4-12 carbon numbers, commonly referred to as C4-C12) in the gas station contains some percentage of ethanol (C2) as additive. However, long-chain alcohols (C4-C19) are regarded as better alternatives for ethanol in gasoline or jet/diesel fuels. These higher alcohol dopants can be produced from short-chain ones (such as methanol, ethanol and propanol). Sustainable biomass resources (for example, straw or wood residues in farmland) can be utilized to get lower alcohols via a fermentation (a process widely used in brewery long time before).

Recently, a research group from the Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of the Chinese Academy Sciences has developed novel catalysis routes to convert low alcohols to higher ones.

The jet fuel (mainly C9-C16) additives for aeroplane can be produced in this way. An efficient metal/carbon catalyst (with palladium as active component) was screened and designed for the highly selective transformations. Long-chain (C8-C19) alcohols or ketones (with similar structure to alcohols), components for renewable jet/diesel fuel, were therefore obtained in good-to-high selectivity (>90%) by using the novel palladium catalyst. Notably, the catalytic system showed high stability and recyclability under hydrothermal reaction conditions. As far as we know, this is the first report for the direct upgrading of short chain alcohol mixtures (isopropanol-butanol-ethanol or combined with biomass-derived alcohols). Through control experiments and catalyst characterization, it is supposed that the high selectivity originated from the promotion of butanol self-condensation and consecutive activation of C7 and C8 intermediates for further condensation over palladium metal. This work was recently published on ChemSusChem.

Another work from the same group of QIBEBT focused on the condensation of two kinds of low alcohols (methanol and bio-ethanol) to produce a higher alcohol (namely isobutanol, a C4 alcohol) with an iridium/carbon catalyst. The isobutanol selectivity can reach as high as 90%. Note that the branched-chain isobutanol has higher octane numbers (a standard measure of the performance of a fuel) than its straight chain counterpart. The catalyst system also exhibited good water tolerance, which is a key factor to be considered for future industrial application. This study was published on Green Chemistry.

Figure 1. Scheme for sustainable jet/diessel fuels production from biomass (Image by QIBEBT)

References:

1. Selective upgrading of ethanol with methanol in water for the production of improved biofuel – isobutanol, Green Chemistry, 2016, 18, 2811-2818.

2. Highly Selective Upgrading of Biomass-Derived Alcohol Mixtures for Jet/Diesel Fuel Components, ChemSusChem, 2016, DOI: 10.1002/cssc.201601152.

Contacts: Prof. MU Xindong; Dr. XU Guoqiang

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Email: muxd@qibebt.ac.cn; xugq@qibebt.ac.cn