Scientists Turn Inulin Resources into Ethanol and FOS

The sunflower family plant Jerusalem artichoke has been regarded as an important sustainable feedstock in China. The amazing plant can thrive in infertile soil, without competition with farmland for food plants. The plant tuber contains 60-70% of sugars (also known as inulin). The sugars can be used as versatile resources to generate varying bioenergy, bio-based materials, pharmaceutical, and food. For example, ethanol and fructo-oligosaccharides (FOS) are two key products originated from inulin. However, the sugar conversion efficiency needs to be improved.

Recently, the Microbial Resource Group from Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) of Chinese Academy of Sciences, has developed two easy and effective processes for ethanol and FOS production from inulin resources, respectively.

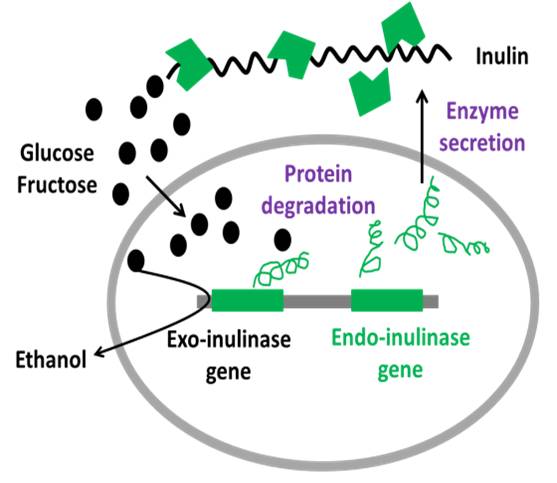

The researchers rationally engineered a natural yeast strain to produce ethanol by a one-step bioprocess. In the process, the fermentation of 250 g/L raw Jerusalem artichoke tuber powder using the strain presented an ethanol concentration of 81.8 g/L and a productivity of 3.1 g/L/h. This is the highest productivity reported up to now in ethanol fermentation from inulin resources. The study has demonstrated a promising potential for the pilot-scale production of fuel ethanol from Jerusalem artichoke. The results were published in the journal Biotechnology for Biofuels.

The same group also developed another efficient one-step bioprocess to produce high-content (approximately 90%) FOS from inulin by yeast. FOS, a well-accepted functional food, can efficiently adjust the function of gut by increasing the amount of beneficial microorganisms. From 200 g/L chicory inulin at 40 °C, FOS fermentation resulted in a maximum concentration of 180.2 g/L, a yield of 0.9 g FOS/g inulin, and a productivity of 7.5 g/L/h, respectively. Apparently, FOS from inulin showed big advantages, since FOS from sucrose by current technology can only reach 0.6 g FOS/g sucrose. The results were patented in a China Patent (Application No. 2016103904308) and also published in the journal Carbohydrate Polymers.

Figure 1. Consolidated bioprocessing for ethanol production from Inulin resources (Image by QIBEBT)

Reference:

1. Engineering a naturalSaccharomyces cerevisiaestrain for ethanol production from inulin by consolidated bioprocessing, Biotechnol. Biofuels, 2016, 9: 96

2. A one-step bioprocess for production of high-content fructo-oligosaccharides from inulin by yeast, Carbohyd. Polym., doi:10.1016/j.carbpol.2016.06.059

Contacts: Prof. LI Fuli; Dr. WANG Shian

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Email: lifl@qibebt.ac.cn; wangsa@qibebt.ac.cn