Yin and Yang in Electrolyte for Lithium Ion Batteries

Taichi, a kind of traditional Chinese boxing, is called as “the quintessence of the Chinese culture”. The Taichi mainly refers to yin and yang. The conflicting and interdependent relations between the yin and yang are the general rules in the material world.

Commercialized lithium ion batteries, composed of liquid electrolyte, cannot meet the need of power battery with high energy density, high power energy and high safety. It is nowadays a trend to develop gel or solid polymer electrolyte. It would be reasonable to achieve such an electrolyte consisting of rigid frame (polyimide, aramid, polysulfonamide, fiberglass and cellulose) (Progress in Polymer Science, 2015, 43, 136) and flexible ion transport materials (polyvinylidene fluoride, polyacrylonitrile, polyethylene oxide, and polypropylene carbonate) in balancing the ionic conductivity, mechanical strength and dimensional stability. Efficient, safe and reliable power battery with the abovementioned novel electrolyte is the bottleneck of developing new electric vehicles or hybrid electric vehicles.

Herein, a research team led by Prof. CUI Guanglei from the Chinese Academy of Sciences' Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT) has already made substantial progress in developing polymer electrolyte with high safety and reliability for power lithium ion batteries.

“Rigid-flexible coupling”composite gel polymer electrolyte

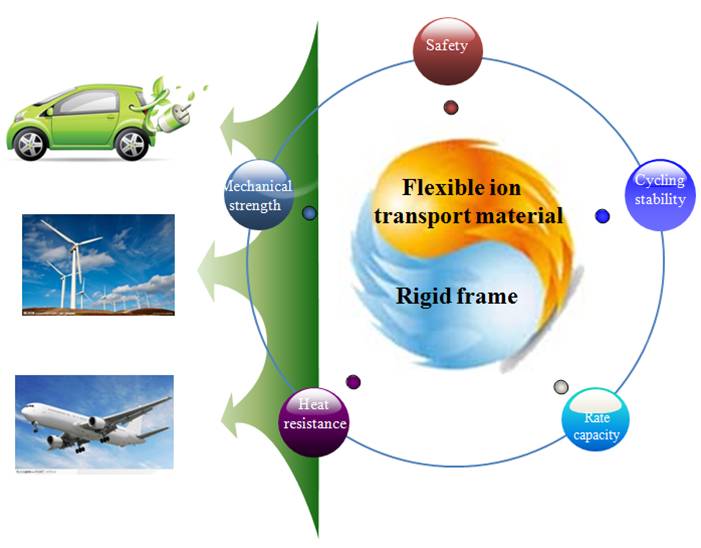

It is essential to explore the so-called “rigid-flexible coupling” composite polymer electrolyte with comprehensive performance in terms of high ionic conductivity, proper mechanical strength, superior heat resistance, wider electrochemical window, and excellent battery performance. Figure 1 shows the designing concept of “rigid-flexible coupling” composite gel polymer electrolyte.

Figure 1. Designing concept of “rigid-flexible coupling” composite gel polymer electrolyte. (Image by QIBEBT)

The advantages (such as outstanding chemical stability and high electrochemical window) of polyvinylidene fluoride (PVDF)-based polymer electrolytes are widely acknowledged. However, their low ionic conductivity, poor mechanical strength, inferior thermal resistance and low electrochemical window limit their further applications. The team herein proposed a scalable and smart strategy to exploit high-performance polyimide (or polysulfonamide) as rigid backbone and use PVDF as ionic transport material. Combining special properties of these two materials, the team successfully developed a new class of rigid-flexible coupling composite polymer electrolyte with comprehensive property (Journal of the Electrochemical Society, 2013, 160, A769; Macromolecular Materials and Engineering, 2013, 298, 806; ACS Applied Materials & Interfaces, 2013, 5, 128). To resolve another problem of low lithium ion migration number, the team developed a new type of single-ion boric acid lithium salts, thus enhance multiple performance of battery (Coordination Chemistry Reviews, 2015, 292, 56; Journal of Materials Chemistry A, 2015, 3, 7773).

In view of the drawback (processing brittleness) of polyacrylonitrile polymer electrolyte, the team tried to explore and fabricate novel material system (ACS Applied Materials & Interfaces, 2015, 7, 4720; Electrochimica Acta, 2015, 157, 191; Electrochemistry Communications, 2015, 61, 84) and have realized the improvement of integrative performance. Moreover, major progress in ultra-high energy lithium-air batteries development has also been made in this group (Advanced Science, 2015, 2, 1500092).

Highly safe all-solid-state polymer electrolyte

No doubt, gel polymer electrolytes play an important role in promoting safety issue of power battery. Nevertheless, polymer lithium batteries containing few liquid organic electrolyte might be suffered from potential safety risks due to leakage, volatility, spontaneous combustion of the electrolytes at elevated temperature or harsh condition. These safety hazards will undermine the confidence of consumers and obstruct the commercialization of electric vehicles or hybrid electric vehicles. Therefore, it is essential to fabricate advanced solid polymer electrolyte for power lithium with excellent safety issue and high energy density.

In view of low electrochemical window and poor mechanical property, the team proposed the "rigid-flexible coupling" concept and herein developed a highly promising solid polymer electrolyte comprised of poly (ethylene oxide), poly (cyano acrylate), lithium bis(oxalate)borate and robust cellulose nonwoven. Our investigation revealed that this new class solid polymer electrolyte possessed comprehensive properties in high mechanical integrity strength, sufficient ionic conductivity and improved dimensional thermostability (Scientific Reports, 2014, 4, 6272).

The low ionic conductivity of poly(ethylene oxide) (PEO)-based solid polymer electrolytes limited their further applications. To solve this bottleneck problem, based on molecular related to ionic conductivity, the team developed a new class of safety-reinforced, wide voltage window and ambient temperature polymer-based solid polymer electrolyte for high-performance all-solid-state lithium batteries. It was demonstrated that such solid polymer electrolyte exhibited comprehensive performance in terms of higher ionic conductivity (4.3×10-4 S cm-1) at room temperature, wider electrochemical window (> 4.6 V), better rate performance and superior cycling stability (90 % after 1000 cycles) at ambient temperature than those of pristine poly (ethylene oxide) solid polymer electrolyte. Relevant research has been published in top international journal (Advanced Energy Materials, DOI: 10.1002/aenm.201501082) (Figure 2).

|

| Figure 2. Preparing route of polycarbonate solid polymer electrolyte. (Image by QIBEBT) |

On the basis of the important advances in polymer electrolyte, QIBEBT has signed a collaboration agreement with a company ZTT International Limited to accelerate its industrialization process.

Reference:

Biomass-derived materials for electrochemical energy storages, Progress in Polymer Science, 2015, 43, 136.

Functional lithium borate salts and their potential application in high performance lithium batteries, Coordination Chemistry Reviews, 2015, 292, 56.

Single-ion dominantly conducting polyborates towards high performance electrolytes in lithium batteries, Journal of Materials Chemistry A, 2015, 3, 7773.

Rigid–flexible coupling high ionic conductivity polymer electrolyte for an enhanced performance of LiMn2O4/graphite battery at elevated temperature, ACS Applied Materials & Interfaces, 2015, 7, 4720.

Heat-resistant and rigid-flexible coupling glass-fiber nonwoven supported polymer electrolyte for high-performance lithium ion batteries, Electrochimica Acta, 2015, 157, 191.

Flexible graphite film with laser drilling pores as novel integrated anode free of metal current collector for sodium ion battery, Electrochemistry Communications, 2015, 61, 84.

A carbon- and binder-free nanostructured cathode for high-performance nonaqueous Li-O2battery, Advanced Science, 2015, 2, 1500092.

Safety-reinforced poly(propylene carbonate)-based all-solid-state polymer electrolyte for ambient-temperature solid polymer lithium batteries, Advanced Energy Materials, doi: 10.1002/aenm.201501082.

Contact: Prof. CUI Guanglei

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Email: cuigl@qibebt.ac.cn