Microalgal Attached Biofilm Cultivation Technology

Attached biofilm cultivation has been the hotspot of microalgae cultivation technology, which has demonstrated very high biomass productivity. However, it is still unknown why the culture of microalgae has high photosynthesis efficiency.

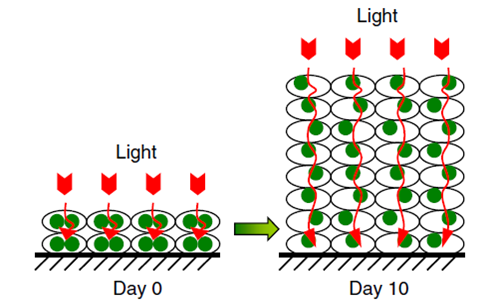

Recently, Prof. LIU Tianzhong and his research team from Qingdao Institute of Bioenergy and Bioprocess Technology (QIBEBT), Chinese Academy of Sciences, revealed the mechanism by analyzing the light penetration property of both algal biofilm and open pond. The growth, photosynthetic oxygen evolution as well as specific growth rate were studied to determine the effective light penetration at different phases of the conventional open pond and biofilm cultivation. Results showed that in a typical 20 cm-deep open pond operated outdoors, all of the algal cells were fully illuminated in the first 3 days of cultivation. As the biomass concentration increased from day 4 to day 10, the light could only effectively penetrate 45.5% of the open pond depth, and then effective light penetration gradually decreased to 31.1% at day 31, when the biomass density reached the maximum value of 0.45 g L-1, or 90 g m-2. While in the attached cultivation system, from day 0 to day 10 when the biomass density increased from 8.8 g m-2 to 107.6 g m-2, almost 100% of the immobilized algal cells inside the biofilm were effectively illuminated due to the continuous reduced chlorophyll content inside the algal cell which allowed the light to travel deeper and deeper (Fig. 1). Higher light penetration efficiency might be the reason why the photosynthetic efficiency was much higher than that of open pond method.

Furthermore, the water footprint is taken to be an important factor to evaluate mass cultivation technology for microalgae. Current cultivation methods of both aqua-suspended open pond and closed photobioreactor (PBR) have huge water footprint. For biofuel production or CO2 mitigation applications, it would destroy the entire superiorities of microalgae over the other higher plant resources and make the microalgae not as ‘green’ as expected. The team at QIBEBT proposed a tactic to minimize the water footprint of the biofilm cultivation, which mainly contains the following rules, e.g. 1) the biofilm was sealed in a moisture saturated chamber, 2) the biofilm was inoculated with a minimum volume of modified medium that contained enough nutrients for cultivation and, and 3) the photobioreactor was aerated with CO2 enriched air stream and the aeration speed is as slow as possible. A narrow chamber biofilm cultivation photobioreactor was newly designed and a serial of experiments were carried out to estimate the minimum water footprint with Haematococcus pluvialis. Results indicated that the proposed water saving tactic was very effective. To produce 1 kg of Haematococcus biomass and astaxanthin, the water footprint was as low as 35.7 L and 1440 L, respectively, which were much lower than the reported cases.

The research was supported by the National Natural Science Foundation of China (41276144), the QIBEBT Director Innovation Foundation, and Science and Technology Development Planning of Shandong Province (2013GHY11520).

Figure 1. The schematic model for the chlorophyll and light distribution inside the attached cultivation biofilm ofS. dimorphus. (Image by QIBEBT)

References:

The difference in effective light penetration may explain the superiority in photosynthetic efficiency of attached cultivation over the conventional open pond for microalgae, Biotechnology for Biofuels, 2015, 8, 49.

The water footprint of biofilm cultivation ofHaematococcus pluvialisis greatly decreased by using sealed narrow chambers combined with slow aeration rate, Biotechnology Letters, 2015, DOI: 10.1007/s10529-015-1864-7.

Contacts:

Prof. LIU Tianzhong

Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences

Email: liutz@qibebt.ac.cn