QIBEBT Developed Biofuel Cell Based on Microbial Surface Displaying Enzyme

The Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences (QIBEBT-CAS) developed a novel approach for assembly of enzymatic biofuel cell (BFC), which can directly convert energy from xylose into electrical energy using xylose dehydrogenase (XDH) surface displayed bacteria (XDH-bacteria). The strategy not only overcomes the conventional limitations such as the undesirable long-term durability and electron transfer issue in the development of BFCs, but also solves the high-cost and poor stability of the purified enzymes.

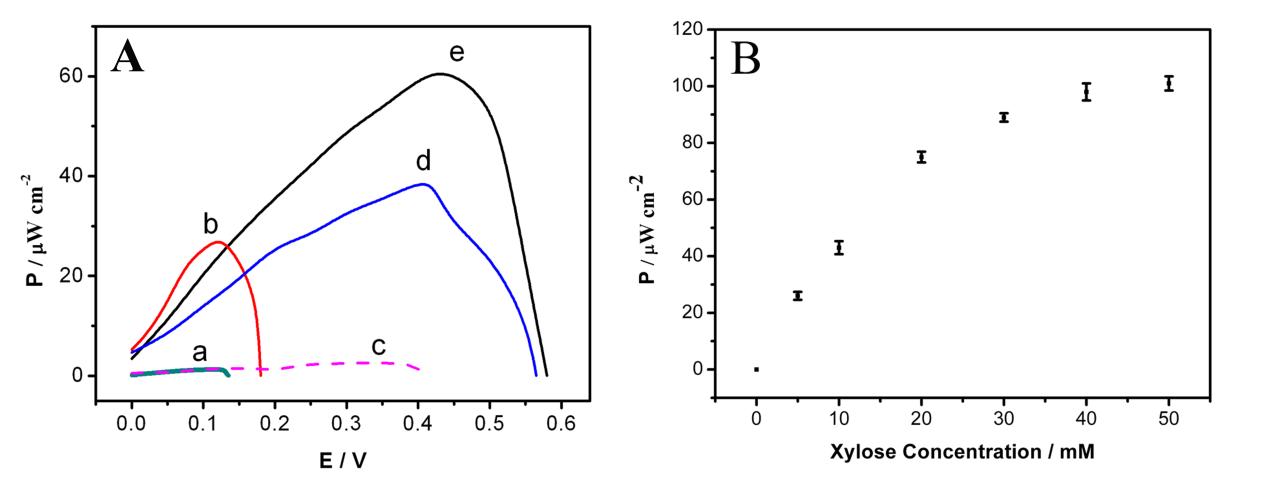

As introduced by Prof. LIU Aihua, leader of the Biosensing Group at the QIBEBT, the one-compartment biofuel cell contains XDH-bacteria /poly (brilliant cresyl blue) (PBCB) /multiwalled-carbon-nanotubes (MWNTs) modified glassy carbon electrode (GCE) (XDH/PBCB/MWNTs/GCE) as the bioanode, and bilirubin-oxidase /MWNTs /GCE as the biocathode. The as-assembled BFC showed a maximum power density of 63 μWcm-2 at 0.44 V with an open circuit potential of 0.58V (Figure 1, curve e), which is much better than other bioanodes including XDH/PBCB/MWNTs/GCE (Figure 1, curve d).

Xylose is an important monosaccharide that extensively exists in the cellulose fermentation industry, comprising about 17-31% of lignocellulose materials. Conventionally, the conversion of xylose to fuel ethanol is achieved either by a thermochemical method or microorganisms fermentation approach. However, the thermochemical process requires a harsh condition which is energy-consuming. On the other hand, microorganism fermentation process is very slow with a poor yield, most probably due to the low resistance of microorganisms to higher concentrations of ethyl alcohol. Another disadvantage of these processes is that there are various by-products, primarily acetic and lactic acids, which will lower the utilization efficiency. In contrast, enzymatic bioelectrocatalytic oxidation of xylose would open a new avenue for using degradation product of agricultural wastes as a direct energy source.

Additionally, Prof. LIU stated, his group has developed a series of electrochemical biosensors on basis of microbial surface displaying systems. The proposed methods can be applicable to sensitive, selective and rapid measurement of either xylose or glucose, or simutaneous detection of both in complicated matrix including beverage and degradation products of straw. Related work has been published in Analytical Chemistry 2012, 84, 275-282 and Biosensors & Bioelectronics 2012, 33, 100-105; 2013, 42, 156-162; 2013, 45, 19-24.

This research was funded by the National Natural Science Foundation of China and the Knowledge Innovation Project, Chinese Academy of Sciences.

Link of the publications:

http://www.sciencedirect.com/science/article/pii/S0956566313000298

http://pubs.acs.org/doi/abs/10.1021/ac202513u

http://www.sciencedirect.com/science/article/pii/S095656631100827X

http://www.sciencedirect.com/science/article/pii/S0956566312007567

http://www.sciencedirect.com/science/article/pii/S0956566313000535

Contact:

Prof. Dr. LIU Aihua

Email: liuah@qibebt.ac.cn