QIBEBT Announced a Novel Microalgal Mass Cultivation Technology

|

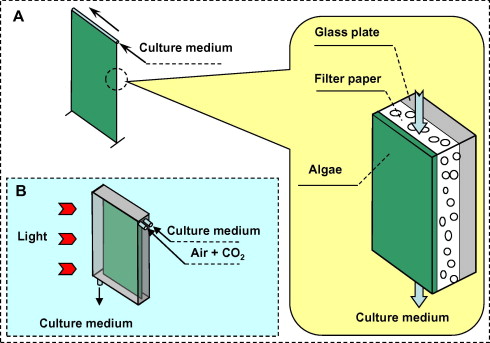

| Fig. 1 The schematic diagram of attached cultivation technology for microalgae (Image by Prof. LIU Tianzhong’s Group) |

Based on these findings, the research team also proposed a novel principle of photobioreactor design based on two strategies of solar dilution to increase the cultivation productivity. One is the solar dilution by increasing the illumination area and another is the light-dark cycle with proper frequencies. Totally 3 pieces of related Chinese patents of the photobioreactor structure are now under examinations (201210051552.6, 201210048910.8, 201210051158.2).

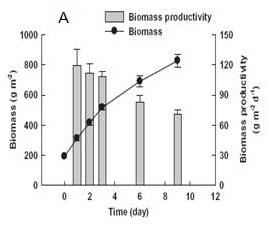

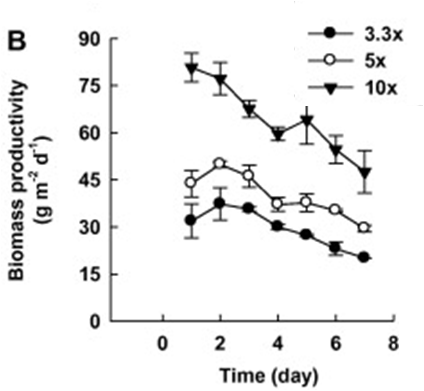

The biomass production potential was further investigated under indoor and outdoor conditions with the novel designed photobioreactor. Results showed that biomass productivities of 60-120 and 50-80 gm-2d-1 were obtained under indoor and outdoor conditions, respectively, which were 300-500% higher than conventional open ponds. Additionally, the water requirement was potentially reduced 95% for this bioreactor, so that the contamination control and scale-up might be readily achieved in the future large-scale facilities (Bioresource Technology, 2013, 127: 216-222). This technology has been also successfully applied in the mass cultivation of other microalgae like Spirulina. The outdoor biomass productivity reached 50-60 gm-2d-1, a 400% increase compared with open ponds, indicating significant potentials of this attached cultivation technology in impelling the upgrade of traditional economic microalgal industry.

|

|

| Fig. 2 The biomass productivity of Scenedesmus obliquus under indoor (A) and outdoor (B) conditions (Image by Prof. LIU Tianzhong’s Group) | |

To further prove the technology, Prof. LIU’s team is constructing an attached microalgal cultivation system in pilot level of 200 m2 for oleaginous and economic microalgae, which was supposed to be finished in the first quarter of 2013. The above reported novel microalgae mass cultivation technology development was financial support by Ministry of Science and Technology of China and Chinese Academy of Sciences.