Effective Conversion of Lignocellulose into Value-added Cellulosic Materials

With the increasing scarcity of global fossil fuel resources, the synthetic fibers will be more and more restricted. Therefore, in order to meet the market demand, the development of the abundant, biodegradable, environmental friendly fiber materials with diverse functions has been paid extensive attention.

A series of researches of chemical modification and functionalization of fiber materials have been carried out by the Green ChemoCatalysis Group led by Prof. MU Xindong, at Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences; and the research outcomes have been published on Chem. Commun., J. Mater. Chem., etc.

The bleached softwood kraft pulp fibers were converted to dissolving pulp for viscos production by using the coupling of chemical method and enzymatic treatment. After the treatment, the α-cellulose content and cellulose reactivity could be over 90% and 70%, respectively. This approach with simple process and low cost, not only can lead to the value-added utilization of lignocellulose, but also can reduce the dependence of petrochemical resources to chemical fiber industry. The research results were published on the journal of China Pulp & Paper (2011, 30(8): 63-67) and Pulp and Paper (2012, 1(31): 23-27).

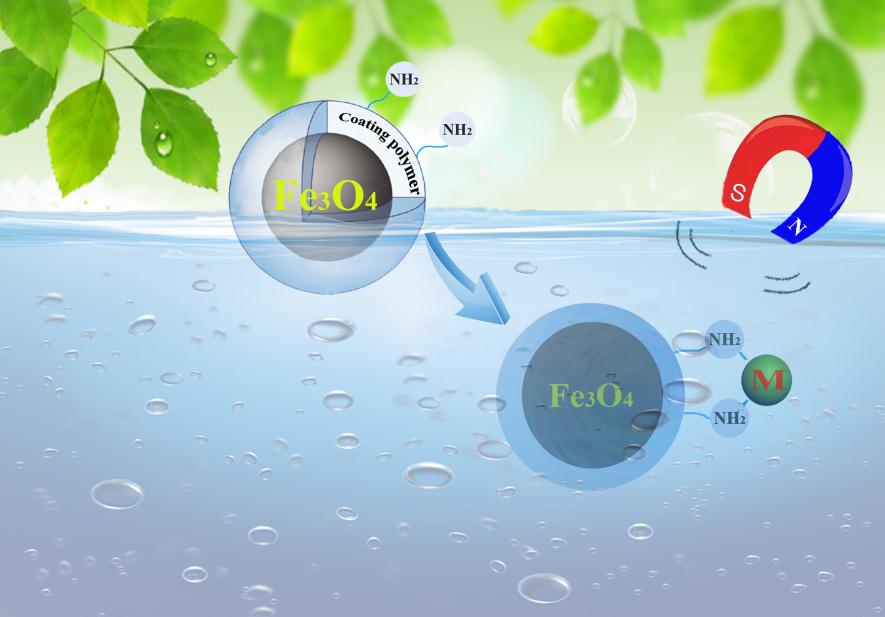

To further enhance the added value of pulp fibers, the cellulose microspheres were synthesized by coating magnetic iron particles with dissolving pulp fibers and chitosan (CN20110447643.7). The synthesized microspheres have excellent function of the adsorption of metal ions, such as Cu2+, Fe2+, and Pb2+. More importantly, the microspheres can be recycled and reused. Thus, this technology has a promising application in the field of wastewater treatment. Also, the research results were published on Chemical Communications (2012, 48(59), 7350-7352) as a back cover article.

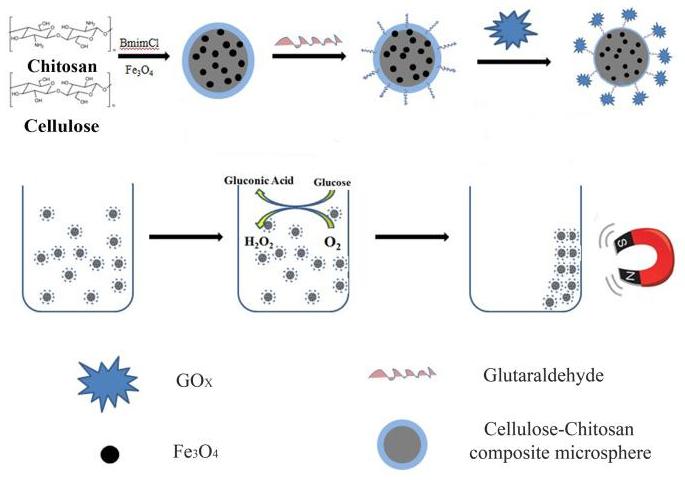

Furthermore, the synthesized microspheres can be crosslinked with glutaraldehyde so that the microspheres can be applied to enzyme immobilization. It was found that the enzyme activity of the immobilized glucose oxidase could still remain 84.2% of the initial activity after reused 15 times. This approach has large potential applications in biological engineering, catalysis, medicine and other related fields, and the related results were published on the Journal of Materials Chemistry (2012, 22(30), 15085-15091).

The above research works were supported by 863 Program of the Ministry of Science and Technology, National Natural Science Foundation of China, Natural Science Foundation of Shandong Province and Qingdao Major Research Program.

Figure 1. The scheme of the process for the adsorption of metal ions by cellulosic microspheres and recycling of the microspheres (Image by Prof. MU Xindong’s Group)

|

| Figure 2. The scheme for the immobilization of glucose oxidase by cellulosic microspheres and the reuse of the synthesized microspheres (Image by Prof. MU Xindong’s Group) |

Publication Links:

1. Chemical Communications, 2012, 48, 7350-7352, http://pubs.rsc.org/en/content/articlelanding/2012/cc/c2cc17795a/unauth

2. Journal of Materials Chemistry, 2012, 22 , 15085-15091, http://pubs.rsc.org/en/content/articlelanding/2012/JM/c2jm33033d

Contact:

Prof. MU Xindong

Qingdao Institute of Bioenergy and Bioprocess Technology

Chinese Academy of Sciences

Tel: +86-(0)532-80662723

Email: muxd@qibebt.ac.cn