Non-food Bioethanol Production Improves via CBP

Jerusalem artichoke is a kind of new energy plant, which can grow well on poor land without competition for good quality fertile land and possesses high tolerance to frost and plant diseases. Jerusalem artichoke tubers or the residue of Jerusalem artichoke from sugar industry are promising feedstock for bioethanol production. Inulin, the major polysaccharide contained in Jerusalem artichoke tubers, can be converted into bioethanol by consolidated bioprocessing (CBP), which integrates inulinase production, inulin hydrolysis and ethanol fermentation into one step.

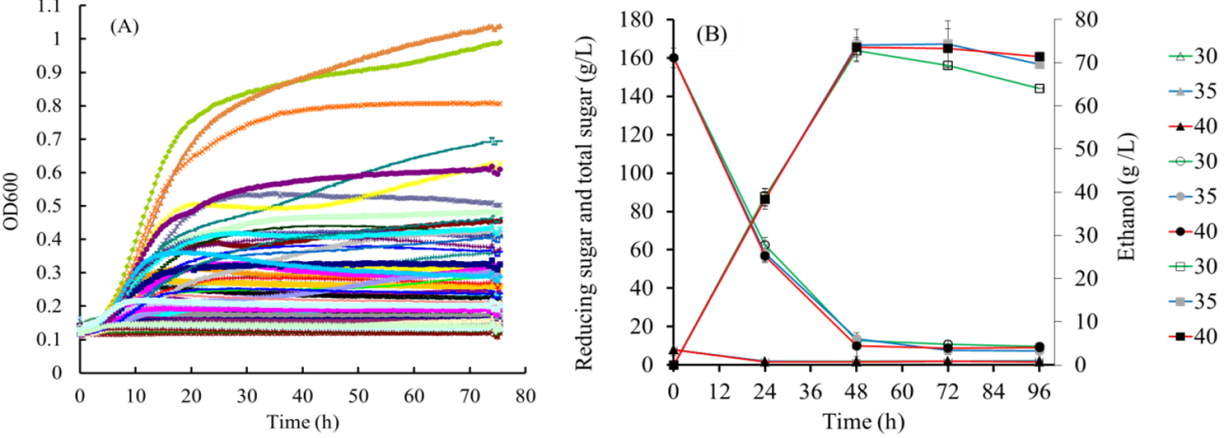

The budding yeast Saccharomyces cerevisiae is a suitable and widely used industrial microorganism for large-scale ethanol fermentations. However, it has traditionally been considered to be inulin-negative yeast. Prof. LI Fuli’g research group recently discovered a stress tolerant inulin-utilizing S. cerevisiae strain in yeast resource investigation. The strain fermented 200 g/L Jerusalem artichoke powder at 40oC to produce 65.2 g/L of ethanol and the yield is 79.7%, which are the highest values reported up to now in ethanol fermentation from Jerusalem artichoke by non-engineering S. cerevisiae strains. Traditional ethanol fermentation temperatures are 30oC to 35oC, and the cost will be significantly reduced when the temperature increases by 5oC. The strains found by this research group can perform ethanol fermentation at 40oC representing the advantage of the strain. These results have been filed a China's patent (ZL201010111324.4) and published in the Appl Microbiol Biotechnol (2012) 95:1359-1368.

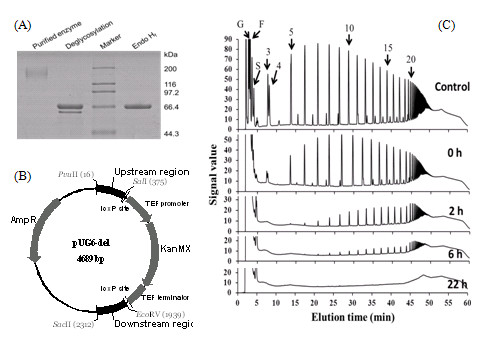

Genetic mechanisms of inulin hydrolysis in S. cerevisiae remain unknown, although strains capable of utilizing inulin have been found. Prof. LI’s group reported functional characteristics of invertase SUC2 and demonstrated that SUC2 is the key enzyme responsible for inulin metabolism in S. cerevisiae by molecular and genetic methods. These results have been published online in the Appl Environ Microbiol (DOI: 10.1128/ AEM.02658-12).

A novel yeast species capable of utilizing inulin at high efficiency was isolated in yeast resource investigation. A novel extracellular exoinulinase was purified and characterized from the novel yeast, and the gene encoding the enzyme was successfully cloned. After heterologous expression of the inulinase gene and that from Kluyveromyces marxianus in S. cerevisiae, the transformants employing the inulinase gene from the novel yeast showed better growth on inulin. These findings have been published online in the Appl Microbiol Biotechnol (DOI 10.1007/s00253-012-4108-y).

The finding of inulin hydrolytic enzyme in S. cerevisiae and the novel exoinulinase provide new ideas for improvement of yeast strains for ethanol fermentation from Jerusalem artichoke by CBP. Inulin with high degree of polymerization (DP) is difficult to be hydrolyzed. Endoinulinase can digest inulin with high DP into oligosaccharides, which can easily be hydrolyzed by exoinulinase. Thus, introduction of endoinulinase genes into S. cerevisiae is expected to improve its inulin fermentation. Based on this assumption, Prof. LI’s group has been performing heterologous expression by introducing an endoinulinase gene into S. cerevisiae as well as the novel exoinuliase gene found by them. The aim of the research in next phase is to obtain engineered S. cerevisiae strains that can give a yield of over 90% in ethanol fermentation of 200 g/L of Jerusalem artichoke powder by CBP at 40 oC.

|

| Fig. 1. Ethanol fermentation by S. cerevisiae from Jerusalem artichoke powder. (A) Screening of S. cerevisiae strains growing on inulin; (B) Ethanol fermentation at different temperature. (Image by Dr. WANG Shi’an) |

|

| Fig. 2. Enzymes with inulin hydrolytic activity. (A) Protein purification; (B) Vector for gene deletion; (C) Kinetic hydrolysis of commercial chicory inulin by purified SUC2 from S. cerevisiae. (Image by Dr. WANG Shi’an) |

Paper links:

1. Appl Microbiol Biotechnol, 2012, 95:1359–1368. http://www.springerlink.com/content/mm26x2v824wl17n6/

2. Appl Microbiol Biotechnol,available online 24 May 2012, DOI 10.1007/s00253- 012-4108-y. http://www.springerlink.com/content/84533v34l6582747/

3. Appl Environ Microbiol, available online26 Oct 2012, DOI: 10.1128/AEM. 02658-12. http://aem.asm.org/content/early/2012/10/22/AEM.02658-12.full.pdf+html

Contact:

Prof. Dr. LI Fuli

Microbial Resources Group

Qingdao Institute of Bioenergy and Bioprocess Technology

Chinese Academy of Sciences

Email: lifl@qibebt.ac.cn

Website: http://www.bioenergychina.org/mr/index.html