Research on Ethanol Production Highlighted by Green Car Congress

The research on ethanol production from brown algae by employing a novel thermophilic bacterium at QIBEBT (Biotechnology for Biofuels, 2016, 9: 81) was highlighted by Green Car Congress.

China team identifies new thermophilic bacterium for direct production of ethanol from brown algae

Researchers from the Shandong Provincial Key Laboratory of Synthetic Biology, Qingdao Institute of Bioenergy and Bioprocess Technology, Chinese Academy of Sciences have identified and characterized the first thermophilic bacterium capable (Defluviitalea phaphyphila) of direct conversion of brown algae to ethanol.

D. phaphyphila Alg1 can simultaneously utilize mannitol, glucose, and alginate to produce ethanol. In an open access paper on their work published in the journal Biotechnology for Biofuels, they report high ethanol yields of 0.47 g/g-mannitol, 0.44 g/g-glucose, and 0.3 g/g-alginate.

Brown algae are a large group of marine seaweeds including almost 1800 species of macroalgae with a characteristic olive-green to dark brown color derived from fucoxanthin. … The technology for the mass production of macroalgae has been developed significantly in China and Asia over the last 50 years. Notably, China contributes 72% of global aquaculture-based macroalgae production, including the genera of Laminaria (reclassified as Saccharina for some species, brown algae), Undaria (green algae), Porphyra, and Gracilaria (red algae). Brown algae have complex sugar composition, mainly including alginate, mannitol, and laminarin. Alginate is the unique structural polysaccharides in brown algae… The content of alginate varied from 20 to 40% of dry weight among different species. Mannitol and laminarin are considered as reserve carbohydrates in many brown algae species, which are mostly accumulated in summer. Mannitol is a sugar alcohol form of mannose, while laminarin is a linear polysaccharide… The content of mannitol and laminarin in some species can reach as high as 25 and 30 %, respectively, at the beginning of autumn.

… The direct bioconversion of brown algae to produce bioethanol cannot be easily achieved because of their diverse carbohydrate components. It is difficult for one microorganism to ferment all saccharides for biofuel production.

—Ji et al.

In earlier work, the identified a strain of Defluviitalea phaphyphila from coastal sediments. Analysis of the genome indicated that the strain has an integrated brown algae-degrading system.

They evaluated the growth and ethanol fermentation properties of D. phaphyphila by employing alginate, mannitol, or glucose (laminarin monomer) as substrates.

They also used an artificial mixed sugar simulating the main components of brown algae with a ratio of alginate:mannitol:glucose = 5:8:1 (3% total sugar).

A total of 7.8 g/L ethanol and 1.2 g/L acetic acid were produced with a consumption of 24.2 g/L total sugars. The ethanol-to-acetate ratio and ethanol yield were calculated to be 6.5:1 and 0.32 g/g-total sugar, respectively.

It can be concluded that D. phaphyphila Alg1 could simultaneously saccharify and ferment the three main components of brown algae, and although these components have different oxidoreduction potentials, reducing equivalents are well balanced and metabolic flux is directed into ethanol production in this strain.

—Ji et al.

They also obtained an ethanol yield of 0.25 g/g-biomass in fermenting unpretreated kelp.

This novel bacterium provides a potential gene-manipulable platform for high-value chemical production from brown algae at elevated temperature.Ji et al.

Resources

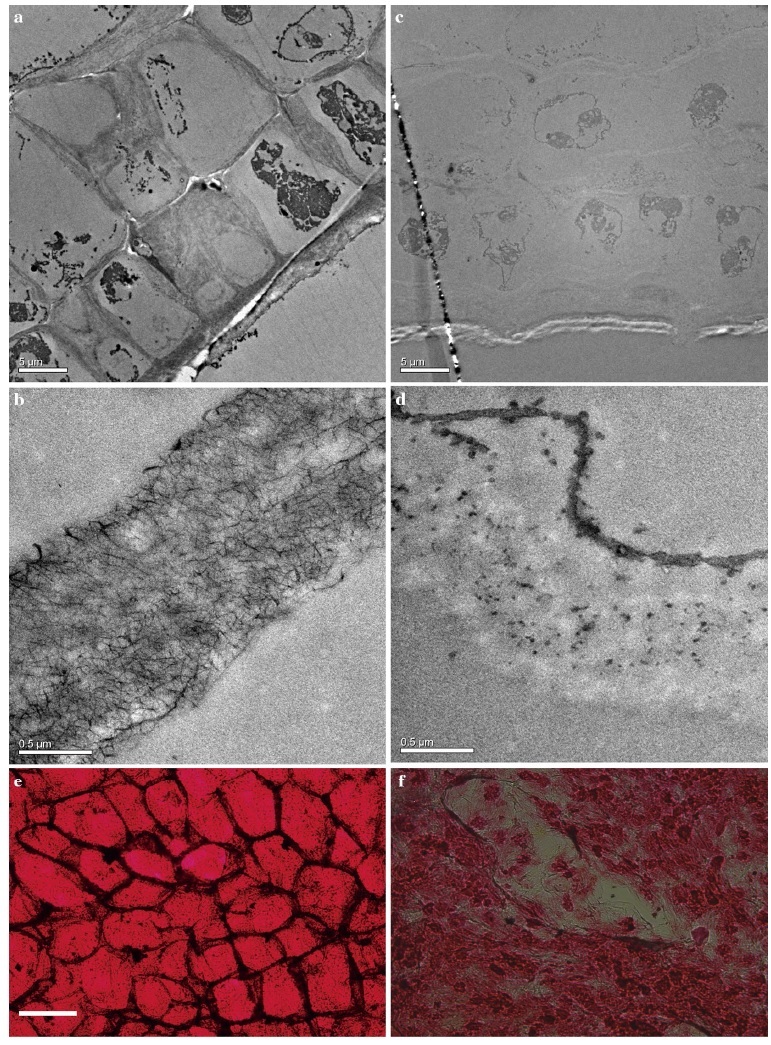

Figure 1. Transmission electron microscope (TEM) and optical microscope images of brown algae samples, unfermented brown algae (a,b,e), and brown algae after fermentation (c,d,f).e,fstained with azaleine (Image by QIBEBT).